Date added: 2025-02-07

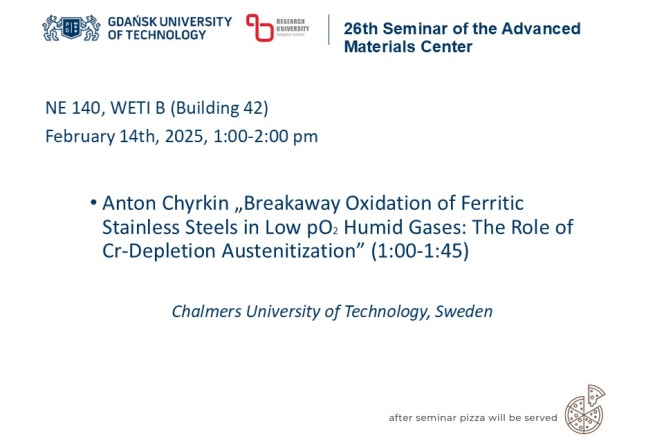

The 26th Seminar of Advanced Materials Center

We cordially invite you to the 26th seminar of the Advanced Materials Center, which will take place on February 14th, 2025 (Friday) at 1:00 p.m. in Room NE140 (building 42, new ETI).

Dr. Anton Chyrkin from the Department of Chemistry and Chemical Engineering, Chalmers University of Technology will present a lecture entitled "Breakaway Oxidation of Ferritic Stainless Steels in Low pO2 Humid Gases: The Role of Cr-Depletion Austenitization".

After the seminar, we traditionally invite you for pizza!

Short BIO

Dr. Anton Chyrkin studied physical chemistry at University of Kyiv (2001-2006). He did his PhD (2012) about oxidation-induced phase transformations in Ni-base alloys at Technical University of Aachen (RWTH) in Germany working with Prof. W.J. Quadakkers. Dr. Chyrkin made his habilitation at University of Kyiv, Ukraine in 2019. Since 2017 Dr. Chyrkin is working at Chalmers university of technology, Gothenburg, Sweden at the High Temperature Corrosion competence center. Currently, he is a MSCA fellow (Marie Curie scholarship). Dr. Chyrkin is an expert in high-temperature corrosion of stainless steels and Ni-base alloys, diffusion modeling of dynamic phase transformations in alloys and coating systems as well as lifetime prediction.

Abstract

High temperature alloys rely in their environmental resistance on the formation of protective, slow growing, adherent oxide scales. The presence of water vapor and hydrogen in both high and low oxygen potential atmospheres alters the oxide scaling mechanism accelerating chromium consumption and thereby promotes depletion of Cr undermining protectivity of the Cr2O3 scale. Ferritic stainless steels (FSS) are known to suffer from accelerated breakaway oxidation in steam and H2/H2O gas mixtures. Like the dual atmosphere effect, breakaway oxidation in H2/H2O is most intense around 600°C. However, some steel grades perform poorly in H2/H2O above 900 °C as well. The mechanism of this high-temperature breakaway is still insufficiently understood and is subject to debating.

The goal of this study is to elucidate the critical role of the a-to-g phase transformation in ferritic steels upon oxidation-induced Cr-depletion. FeCr-base model alloys were designed to simulate a suppression of the austenitization via stabilizing the BCC structure (alloying with Mo), lowering the oxidation rate (alloying with Si), and increasing the Cr-reservoir to 30 wt.%. The exposed alloy specimens were examined using metallography, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDX).

FeCr-alloys are demonstrated to undergo an a-to-g phase transformation between 10.7 and 12.2 wt. % Cr at 900°C. One the alloy surface Cr concentration drops below 12 wt. %, a grain of Fe-FCC forms in which Cr diffusion is one order of magnitude slower compared to the BCC lattice. The slower diffusion provokes a further local Cr depletion to a critical level, resulting thereby in oxidation of Fe providing that oxygen potential allows it. A diffusion analysis predicted protective behavior for ferritic (BCC) Fe-18Cr at 900°C and loss of protection once austenite (FCC) is formed. Elimination of the a-to-g phase transformation resulted in protective behavior (as well as a higher Cr-reservoir in Fe-30Cr prevents a critical Cr surface depletion to 12 wt. % along with the austenitization and provides thereby protectiveness.

-

2026-01-26

Polonium results [updated 21.01.26]

-

2026-01-20

Additional call under the Francium program