Date added: 2025-04-10

Next-Generation Batteries To Be Developed at GdańskTech

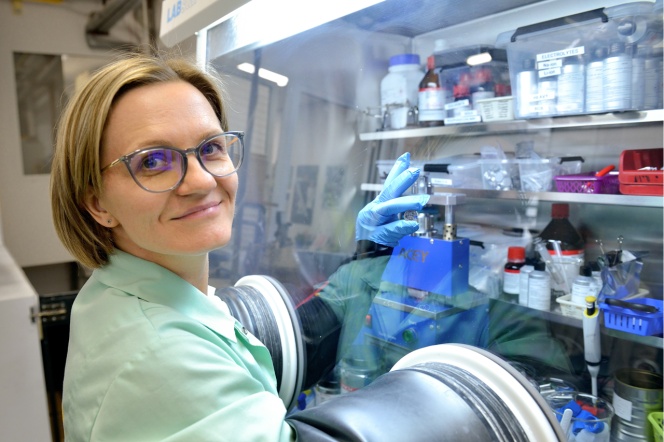

Monika Wilamowska-Zawłocka, PhD, DSc, Eng., Professor at the Department of Energy Conversion and Storage at the Faculty of Chemistry, Gdańsk University of Technology, has just become a laureate of the Swiss-Polish Cooperation Program (Research and Innovation, Applied Research) and has received over PLN 4.3 million in funding for research into materials for batteries that do not contain critical raw materials. The project will be carried out in collaboration with the Swiss research institute Empa – Swiss Federal Laboratories for Materials Science and Technology and the company Siloxene AG.

An Alternative to Graphite: High Capacity and Greater Stability

A standard high-power battery used in drones or cars consists of an anode based on graphite and a cathode made from lithium nickel manganese cobalt oxide compounds.

"In our next-generation lithium-ion batteries, we will use silicon oxycarbides (SiOCs) as matrices for nanoparticles forming alloys with lithium, such as elemental silicon or tin. SiOCs are polymer-derived ceramic materials (PDCs), which allows for synthesis methods that ensure high uniformity in nanocomposites combining metals and ceramics" says Professor Wilamowska-Zawłocka. "Silicon oxycarbides provide not only good mechanical and chemical strength but also electrochemical activity toward lithium ions, which will enable the development of anode materials with significantly higher electrical capacity than the commercially used 'critical' natural graphite," she explains.

As the researcher emphasizes, the elements forming alloys with lithium offer much higher electrical capacity than traditional graphite anodes, making them a key means for increasing the capacity of anodes in next-generation lithium-ion batteries.

"However, their major drawback is a significant volume change during charging and discharging cycles, which leads to degradation and loss of performance over time," Professor Wilamowska-Zawłocka explains. "This makes commercial batteries containing silicon still rare, but many companies are working on developing such anodes. Our task will be to embed silicon and tin nanoparticles in a properly designed SiOC matrix, which will minimize these problems."

Recovery of Critical Raw Materials from Lithium-Ion Cells

In addition to research on new battery materials, the team led by Professor Monika Wilamowska-Zawłocka (under the SONATA BIS NCN program grant) is developing processes for recovering critical raw materials from used lithium-ion cells for reuse in new batteries.

The scientists are working on economically viable and environmentally friendly recycling strategies to recover various battery components, including active anode material (graphite), cathode material (cobalt, nickel, manganese), current collectors (copper, aluminum), and lithium.

"Companies worldwide are already recovering raw materials from lithium-ion batteries, but this is still happening on too small a scale, considering the growing number of used batteries of this type. Recycling is not as advanced as for other types of batteries, and direct recycling—recovering the active electrode materials in their original structure—remains at a laboratory scale," emphasizes the researcher. "Meanwhile, according to the analysis and forecasts by the International Energy Agency, by 2030, 100-120 GWh of used batteries from electric vehicles will be generated annually worldwide. Moreover, it is predicted that the number of retired electric vehicle battery modules will increase by 4 million tons by 2030."

Recycling and reusing batteries are therefore essential methods to balance the demand for critical raw materials: cobalt, nickel, lithium, and natural graphite.

"Additionally, cobalt is a major geopolitical issue. Europe must have urban mining facilities dedicated to recycling batteries. This is a very hot topic in Western Europe," emphasizes Professor Wilamowska-Zawłocka.

Sodium Instead of Lithium and Patent Applications

In collaboration with researchers from the Technical University of Darmstadt and Nicolaus Copernicus University (under the BEETHOVEN NCN program grant), Professor Wilamowska-Zawłocka previously conducted a project on innovative and efficient electrode materials for sodium-ion batteries. This project resulted in two patent applications.

"Sodium is the fourth most abundant element on Earth, the second most abundant alkali metal, and the second element after lithium with the most negative electrochemical potential. This means it is the most similar to lithium in terms of electrochemical properties, making it a good candidate for use in high-energy batteries. Most importantly, it is a much more environmentally sustainable alternative," emphasizes Professor Wilamowska-Zawłocka. "Sodium itself is not a critical material, and both anodes and cathodes can be obtained without critical elements. Sodium-ion battery anodes are based on so-called hard carbons, which can be derived from biomass, while cathodes can be based on iron or manganese, not containing the 'critical' cobalt. These materials are cheaper and more environmentally friendly. Additionally, the production of electrode layers can rely on aqueous solutions of binding materials, greatly facilitating later recycling," she enumerates.

However, sodium has its limitations—it is several times heavier than lithium, meaning batteries have lower energy and power density.

"Such batteries are also less durable and lose electric capacity more quickly during multiple charge-discharge cycles, mainly due to the larger size of sodium ions compared to lithium ions. Nevertheless, their development is very dynamic, and we are already seeing the first cars on the market equipped with sodium-ion batteries," adds the researcher.

Research Team Composition: Professor Monika Wilamowska-Zawłocka, Gifty Sara Rolly, PhD, Eng., Balanand Santhosh, PhD, Eng., students: Jakub Olszewski, Emilia Bielska, and Kacper Chodziński.