Date added: 2020-09-29

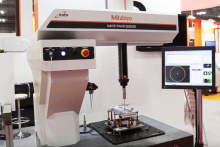

A modern metrology laboratory is being built at GUT

Optical 2D and 3D measuring systems or coordinate measuring machines are just some of the equipment that will be delivered to the new laboratory. The new devices will be used primarily by scientists and students.

– The equipment that we will receive is the highest quality measuring equipment, the university hasn’t had such devices so far - says PhD Michał Dobrzyński. It was primarily thanks to his personal efforts that the laboratory was able to obtain equipment. - Our employees and students will have access to the latest technology in the field of metrology. The laboratory will be able to carry out, for example, a comprehensive analysis of the geometric accuracy of products, which helps scientists in their research.

For researchers and students

The equipment will be handed over in two stages. The first three devices should appear at the Faculty of Mechanical Engineering at the end of this year, and other two in the following year. Mitutoyo Corporation will provide both the equipment and the appropriate software, and will also train designated persons - the caretakers of individual machines.

–Work is currently underway on the preparation of the laboratory - explains PhD Mariusz Deja, GUT professor. – Rooms in which this type of equipment is used must meet special requirements, have precise air conditioning and adequate ventilation so as not to cause a temperature difference and maintain adequate humidity, which is extremely important in such measurements. The results of scientific and research works are published by employees of the Department of Machine Technology and Production Automation in leading scientific journals with the highest scores. Thanks to the obtained measuring equipment, this impressive output of the department will undoubtedly be enlarged by further publications in journals related to the scientific discipline of Mechanical Engineering, which is of key importance for the Faculty of Mechanical Engineering.

Laboratory equipment

The equipment that will be delivered in the laboratory will include:

QUICK IMAGE - 2D optical measuring system that makes it possible to measure products at different heights or multiple planes simultaneously without the need for separate focusing

- QUICK VISION - optical 3D measuring system for fully automated, high-speed measurements

- CONTRACER SV-C3200 - intelligent combination of two stationary devices: contourograph and roughness gauge. This allows one system to reliably measure contours and roughness.

- CMM Crysta-Plus M - manual, economic coordinate machines for 3D measurements. They are used for quick, but demanding workshop measurements, and are equipped with accurate probe positioning and automatic element recognition for easy machine operation.

- Mitutoyo MiSTAR 555 - compact CNC coordinate measuring machine for work in the production hall.

- MeasurLink - a solution for automating and centralizing data collection, inspection data analysis, measurement processes, reducing waste and improving customer relationships.

Joint initiatives with the industry sector

Scientists from the Faculty of Mechanical Engineering are also planning a series of seminars showing the capabilities of machines, intended for the industrial sector - Thanks to such hardware capabilities, we hope for joint activities with companies from the industrial sector from northern Poland, expanding contacts and joint research and development initiatives - said Wojciech Połubok, administrative director The Faculty of Mechanical Engineering.

Collaboration on many levels

The contributor - Mitutoyo is one of the largest suppliers of metrology equipment in the world. It conducts research and development, production and distribution in over 100 countries. Mitutoyo Polska has been operating on the Polish market since 2002, offering the most modern measuring devices and metrological solutions. The company provides measuring devices that define the highest standards in metrology, ergonomics, efficiency and quality management, such as: coordinate measuring machines, vision measuring systems, devices for measuring shape parameters, devices for measuring roundness deviations, optical measuring instruments, laser micrometers, instruments for hardness tests, as well as manual measuring instruments.

– I am very glad that despite the pandemic, this meeting could be organised and we can finalize our project together. I would like to emphasize that apart from the laboratory equipment and software that we provide, Mitutoyo is open to Gdańsk University of Technology also in other aspects. Laboratories, equipment as well as our knowledge and experience in the field of metrology are to serve the university employees so that advanced research works can develop – summarized Jakub Ruszkowski, vice president of the management board of Mitutoyo Polska, who is also a graduate of Gdańsk University of Technology.