Date added: 2021-11-08

He loves sailing, so ... he printed his own canoe. Project by Eng. Maciej Karnowski

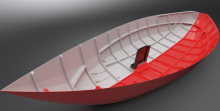

The kayak was printed at home, it is 2.3 m long and 80 cm wide. Maciej Karnowski designed the boat in such a way that it could be transported by a small car.

– I printed the canoe at home and it took me a total of 400 hours – the printer worked about six hours a day. It is much smaller than a standard boat of this type, which usually measures about three meters - noted the graduate.

Maciej Karnowski's kayak looks more like a "canoe". The modular structure of the hull enables the development of the boat. It is open, and in the future it will be possible to mount an engine, mast and rudder.

Cheap and ecological

The material from which the kayak was made is polylactide - obtained from the lactic acid of maize and biodegradable. - This material is generally available when it comes to 3D printing. It is also cheap, the price per kilo is about PLN 40, and the entire boat weighs 12 kg - said Maciej Karnowski.

Connecting smaller elements

The main goal of the engineering thesis was to investigate the possibilities of 3D printers in prototyping large complex objects exceeding the maximum dimensions of the printer. The design must enable printing with the use of the most popular printers such as Anycubic I3, Ender 3, Anet A6, Prusa I3.

It is worth noting that the standard 3D printer has dimensions of 20x20x20 cm and the kayak was made in smaller parts, which were later connected with M4x16 DIN 912 screws, M4 DIN 125 washers and M4 DIN 985 self-locking nuts - this is a total of over 1,200 elements.

Apart from Maciej Karnowski's boat, four vessels made using 3D printing have been created in the world: 3Dirigo, Mambo, Trimech Kayak and 3D System Jim Smith Kayak.

The supervisor of the engineering thesis "Application of 3D printing in kayak prototyping" was Artur Karczewski, PhD, Eng.